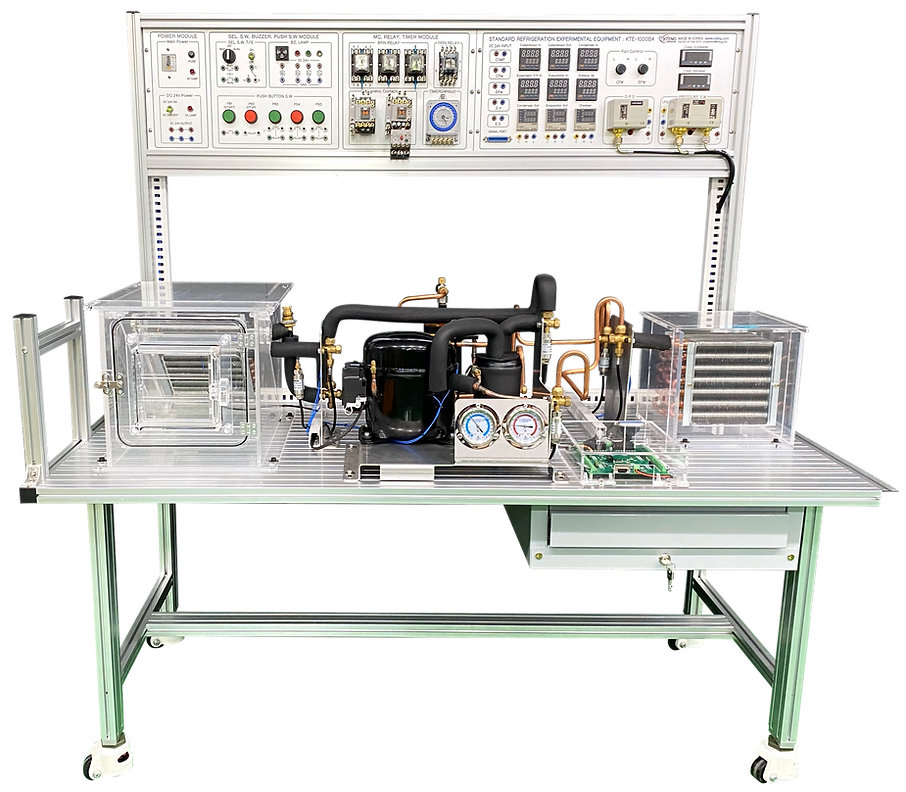

STANDARD REFRIGERATION EQUIPMENT

KTE-1000BA

Equipment Introduction

-

Composition with Compressor, Condenser (with fan motor), Receiver, Filter-dryer, Sight glass,Solenoid Valve, Manual Expansion Valve, Evaporator (with fan motor), High, Low pressure gauge

-

Thess devices run as set up circuit in control panel.

-

DAQ program supply tools with that temperature, pressure, enthalpy, amount of the exchanged heat in each position can be measured in real time, and then saved by Microsoft Excel, so that saved data can be show and analysis by graph

Equipment Characteristics

-

Cycle Composition : Compressor → Condenser → Filter Dryer → Sight Glass → Expansion Value → Evaporator → Compressor

-

Being practicable to operate on manual, thermal control or pump down with connecting by sequence or PLC control system

-

Function for specification of refrigerator performance automatic measuring & data acquisition and system monitoring program

-

Being practicable to measure temperature at each of compressor inlet and outlet, condenser inlet and outlet, expansion valve inlet and outlet, evaporator outlet, inside chamber and outside air using thermocouples of K-type

-

Measure of pressure : Being practicable to measure within the range of –1 ~ 35 bar at each of compressor inlet and outlet, condenser outlet, expansion valve inlet by pressure sensors which are installed

-

Experiment factors

-

Refrigeration effect

-

Compressor work

-

Condensing effect

-

Evaporating latent heat

-

Amount of flash gas at expansion valve outlet

-

Dry ratio and humidity at expension vaLVE OUTLET

-

Coeffcient of performance

-

Temperature and Pressure date wich are measured

-

Being saved on every minute until 1,440 min as excel file after click the "SAVE"

-

Education Contents

-

Standard Refrigeration System Measurement and Analysis Using Software

-

the transition of condensation temperaturePerformance Measurement and Analysis of a Standard Refrigeration System According to

-

the transition of evaporation temperaturePerformance Measurement and Analysis of a Standard Refrigeration System According to

-

Temperature control Sequence Circuit of Standard Refrigeration System Configuration Operation

-

OperationConfiguration Temperature control PLC programming of Standard Refrigeration System

-

Refrigeration SystemPracticing to configure and operation pump down sequence control circuit of Standard

-

Practicing to configure and operation pump down PLC programming of Standard Refrigeration System

Component of Mechanical Standard Refrigeration System

Control Panel Device Component of Standard Refrigeration System

Pressure Switch of Standard Refrigeration System

Magnetic Contactor

Structure of DA 100 (Data acquisition) Program

-

Diagram of Standard Refrigeration System: Compressor → Condenser → Filter Dryer → Sight Glass → Solenoid Valve → Manual Expansion Valve → Evaporator → Compressor

-

Measuring of Temperature, Pressure, Enthalpy

-

Drawing P-h diagram on real time

-

Refrigerating effect (qe), Compressor work (Aw), Condensation effect (qc), Coefficient of Performance (COP)

-

Feature of save data

-

Feature of capture for P-h diagram

Features of DA100 program

-

Monitoring the measured data of temperature and pressure in real time

-

Monitoring the measured data of enthalpy on a refrigeration system in real time

-

Monitoring factors like as refrigeration effect, compressor work, evaporating, latent heat, amount of falssh gas at expansion valve outlet, dry ratio at expansion valve outlet, coefficient of performance in the abstract with temperature and pressure data which are measured in real time

-

Being saved data all temperature, pressure and enthalpy as excel micro office

-

Experiment for drawing a P-h diagram as measured temperature and pressure

Refrigeration Cycle

Video Clips for Product Usage